NetSuite Product Data Management - The research, development and design of new products or the re-design of existing ones is the lifeblood of any manufacturing company, but in many cases, the design and engineering departments are completely disconnected from the ERP system. What that means is engineers spend a lot of their time answering queries from other areas of the company regarding product status, revision levels, design progress, etc. NetSuite offers a host of native collaboration features that makes this information available on a self-service basis across the organization.

Key Benefits

- Ensure production engineering changes propagate end-to-end and are reflected in downstream BOMs, plans and inventories.

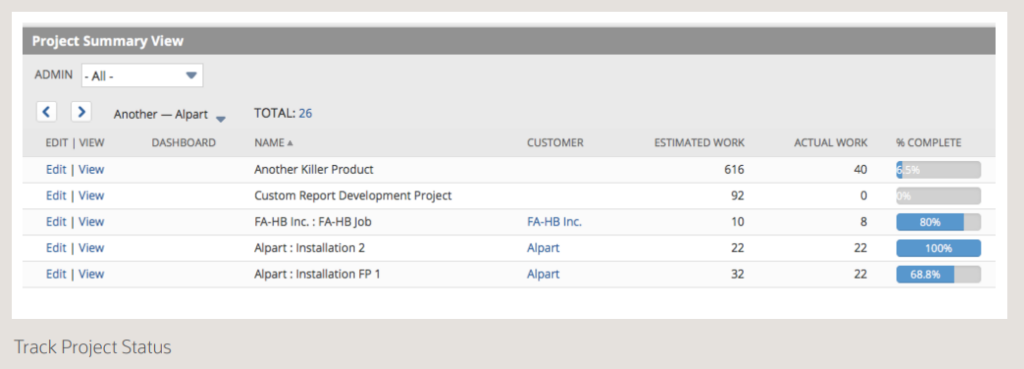

- Extended capabilities for inventory control tracking, planning and costing of items in project controlled environments.

- Deliver more flexibility in costing by supporting comprehensive inventory costing methods including LIFO, FIFO, average, standard and actual costing.

- Streamline team management using ata-glance allocations of people with data, processes and business systems.

- Integrate with other CAD applications and simplify costing by supporting easy importation of BOMs.

Product Data Management

NetSuite has been built from the ground up to support product-based businesses and has robust capabilities to establish and maintain all of the master data you need to run your business including: items, customers, partners and vendors. For any other data you want to track, the SuiteCloud platform can define an unlimited number of additional fields, tables and searches, etc. to provide visibility into any data you want, where you want it—regardless of the source.

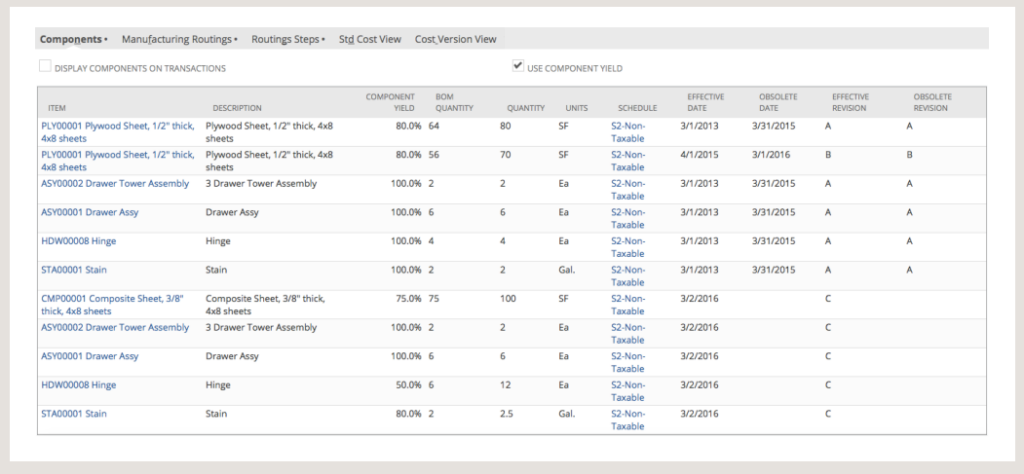

Bill of Materials

Assembly Items have a multi-level BOM attached so you can easily define the components that are to be consumed, the quantities in which you expect to consume them and the expected yield during the manufacturing process.

Location Specific Settings

The NetSuite item master has unique capabilities when it comes to handling companies that manufacture or stock their inventory in multiple locations. The ability to not only define how an item is stocked and replenished but the way that it is manufactured on a location specific basis offers a vast degree of flexibility. For example, the same item could be 100% backflush in one location, materials could be kitted and issued to the work order in another and work centers and labor definitions could be established and tracked in a third.

Routing Definition

NetSuite also offers the ability to track the labor cost and associated overheads critical to a business, and more. Multiple routings can be defined with a default per location. The same routing can be applied to multiple locations.

Are your design and engineering departments feeling disconnected from your ERP system?

Don't let disconnection slow you down. Click here to explore how NetSuite Product Data Management can revolutionize your manufacturing process!

Work Centers and Costing Templates

In order to accurately define the resources required to complete the manufacturing of products, NetSuite allows you to create work centers along with an associated calendar to define availability. The Costing Template allows users to define all of the direct and indirect costs that should be attributed to the manufacturing process each time it is performed.

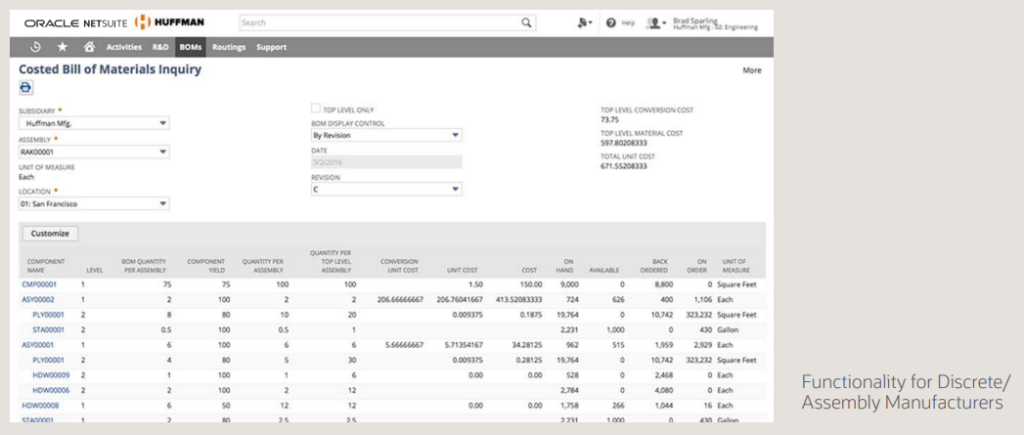

Costed BOM Report

Users who don’t need access to the item master can simply run the costed BOM report to get the required information, with the ability to filter by subsidiary, location, revision and/or effectivity date.

Engineering Change Order

The design and engineering processes doesn’t end when a new product is manufactured and delivered to customers—because now you’ve got a whole new audience who are willing and able to provide feedback whether you want it or not. NetSuite’s ECO feature seamlessly integrates into the rest of the system to make sure that you can quickly and easily capture change requests, document the specifics, use our SuiteApprovals Workflow solution to automate the ECO Approval routing and automatically makes all accepted BOM changes upon implementation.

Revision Control

BOM revisions can be defined either by using effectivity dates or revisions and the view of the BOM components on the item that has the ability to list the complete revision history or be filtered to the most recent one.

)