NetSuite Advanced Manufacturing delivers a single integrated cloud solution that replaces the disconnected systems that are used by manufacturers today. It offers comprehensive functionality and is specifically designed to help manufacturers of all sizes reduce operating

costs, increase revenue and better manage their business and supply chain processes overall. NetSuite Advanced Manufacturing is built on native NetSuite ERP, ensuring manufacturing processes are connected to financial reports, inventory management and outstanding orders in real-time.

Key Benefits

- Improve operational effectiveness

- Reduce ‘Cost to Produce’

- Faster Time to Value

- Unified solution—reduce reliance on third parties

- Improve quality, service and through-put

- Variance management: compare actual versus standard

- One version of the truth

- Integrate Plant to Enterprise (P2E)

- Manufacturing information and intelligence

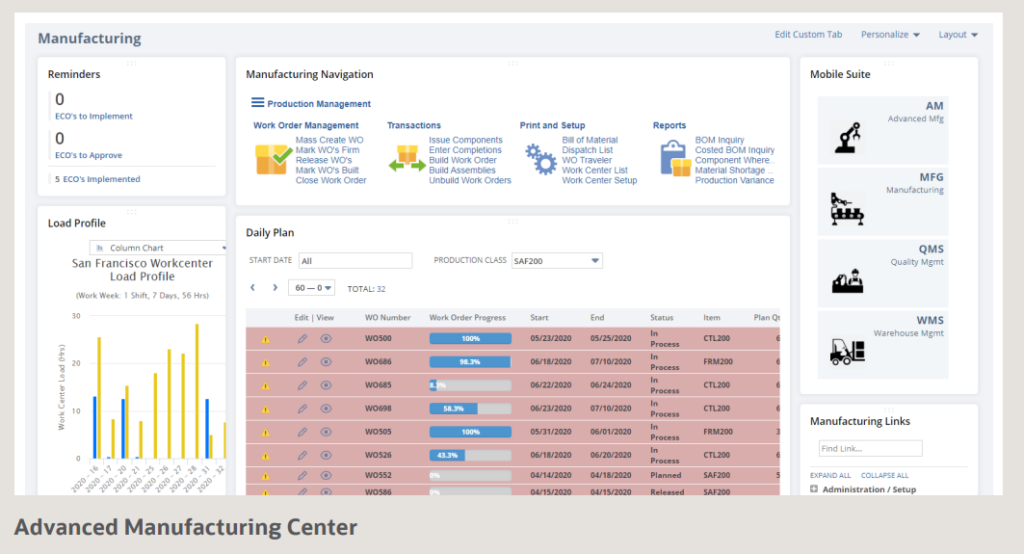

Advanced Manufacturing

NetSuite provides a powerful vertically-integrated solution to help manufacturers manage their business more profitably from Order-to-Cash through Build-to-Ship. NetSuite’s Advanced Planning and Scheduling capabilities enable customers to effectively plan their shop floor and improving capacity and resource utilization, culminating in lower operating costs.

Functionality for Discrete/Assembly Manufacturers

NetSuite Advanced Manufacturing enables Discrete/Assembly Manufacturers to run core business operations by providing deep industry functionality such as parameterized configuration options by location, configurable work order completion logic, and enhanced data collection. The Comprehensive Manufacturing Work Bench Record includes: enhanced operations routings, primary and alternate finite planning parameters, labor requirements and detailed work instructions.

Additional features: configurable Shop Floor Travelers (bar code enabled), Rough-Cut Capacity Planning, Dynamic Schedule Codes, Finite Production Scheduling, enhanced Work Order Release capabilities, supports full Manufacturing Execution System and Manufacturing Operations Management capabilities. Available to OneWorld customers.

Seize total manufacturing mastery with NetSuite Advanced Manufacturing!

Optimize your operations, boost revenue, and take command of your business and supply chain processes. Embrace real-time connectivity between manufacturing and key business areas—financials, inventory, and orders—for seamless efficiency.

Functionality for Batch or Process Manufacturers

Built for batch or process manufacturers, NetSuite Advanced Manufacturing includes all the

functionality outlined for discrete manufacturing as well as an expanded Manufacturing Work Bench Record Structure to include: alternate assets, coproducts, and detailed work instructions for Recipe/Formulation management. Additional functionality supports FIFO material issuance for raw and bulk lot controlled items as well as Batch Travelers (bar code enabled) with automatic Batch Lot ID for full lot track traceability and enhanced material issuance control. Supports full MES and Manufacturing Operations Management capabilities. This is available for OneWorld customers.

Mobile Capability

NetSuite’s native mobile feature set supports fully integrated bar code scanning and wireless tablet functionality for real-time Manufacturing Execution System (MES) reporting capabilities for: Express Data Entry, Work Order Completion (partial or full), Material Issuance, Downtime, as well as actual Labor or Machine Hours reporting by employee ID.

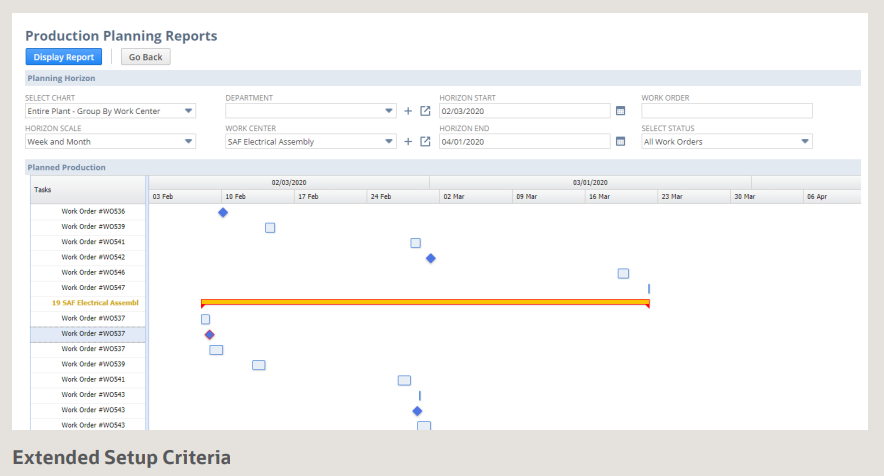

Extended Setup Criteria

Running a manufacturing business requires multiple ways to control how and when you

release work orders and other processes. From the Advanced Manufacturing Admin Console you can find all the settings you need to configure NetSuite to operate in the most efficient way to suit your environment.

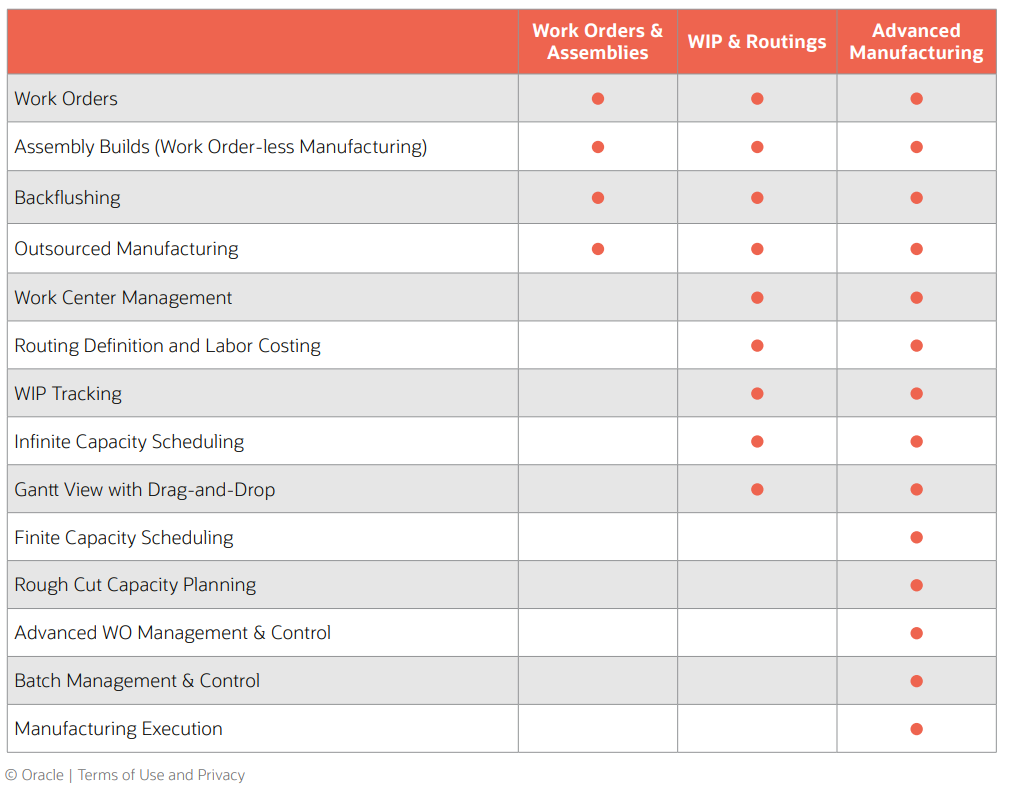

NetSuite Manufacturing

NetSuite offers three options to help you deploy our manufacturing functionality to most closely match your manufacturing needs. In addition, if you have different manufacturing locations you can opt to make the same item in a different way at each location.

- Work Orders & Assemblies works best for companies who do some light assembly but don’t need to track work in process or the labor separately.

- WIP & Routings adds the ability to define work centers, routings, track labor costing, infinite capacity scheduling and provides a Gantt chart with drag-and-drop functionality.

- Advanced Manufacturing provides for those looking for complete control of all aspects of their manufacturing processes including finite capacity scheduling and manufacturing execution.

You can seamlessly upgrade from one edition to another.

)